A team of researchers from Jilin University and Sun Yat-sen University in China has successfully synthesised a lab-grown version of Lonsdaleite, a rare carbon allotrope. Their findings, published in Nature Materials, indicate that this artificial form of Lonsdaleite is at least 40% harder than natural diamond.

What is Lonsdaleite?

Lonsdaleite, named after the British crystallographer Professor Dame Kathleen Lonsdale, was first identified in 1967 within the Canyon Diablo meteorite in Arizona, USA. Unlike conventional diamonds, which have a cubic crystal lattice, Lonsdaleite has a hexagonal structure, contributing to its extreme hardness. Scientists believe that natural Lonsdaleite was formed due to the intense pressure and heat generated when a meteorite struck Earth.

Lab-Grown Lonsdaleite’s Properties

The Chinese research team reports that their synthetic Lonsdaleite exhibits a hardness of 155 GPa (GigaPascals), compared to the typical 100 GPa of natural diamond. In their statement, the scientists highlighted the implications of their discovery, saying:

“Our findings offer valuable insights regarding the graphite-to-diamond conversion under elevated pressure and temperature, providing opportunities for the fabrication and applications of this unique material.”

This suggests that producing Lonsdaleite in a controlled environment could lead to specific industrial applications, particularly in fields requiring extremely durable materials.

Implications for the Jewellery Industry

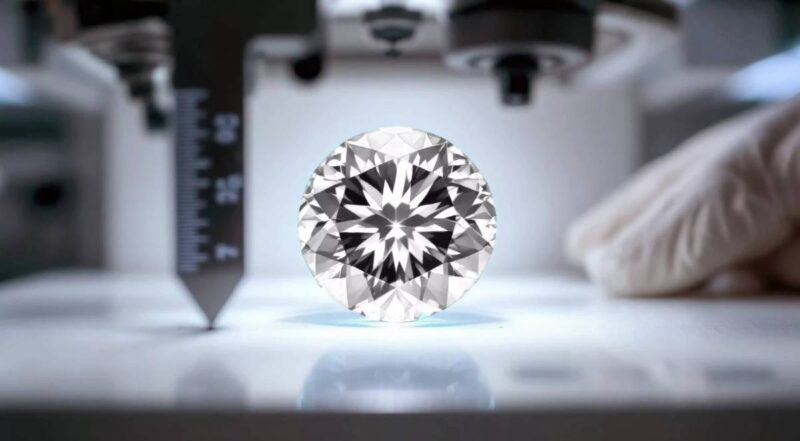

While lab-grown diamonds are well established in the jewellery market, Lonsdaleite is primarily being considered for industrial applications, such as in next-generation superconductors. Its extreme hardness and durability mean it could have specialist uses beyond current synthetic diamonds, but its viability for jewellery remains uncertain.

For now, this development represents progress in synthetic material research, with broader implications for various industries.